Dundee Precious Metals Provides Čoka Rakita Project Update and Additional Results from Infill Drilling Program, including 74 metres at 27.3 g/t Au

September 13, 2024

TORONTO, Sept. 13, 2024 (GLOBE NEWSWIRE) -- Dundee Precious Metals Inc. (TSX: DPM) (“DPM” or “the Company”) today provided an update on its Čoka Rakita project, where the pre-feasibility (“PFS”) is advancing on track for completion in the first quarter of 2025. The Company also reported new assay results from the recently completed PFS infill drilling program.

Highlights

(Refer to Table 1 full results)

- Pre-feasibility study on track: Continue to target completion of PFS the first quarter of 2025.

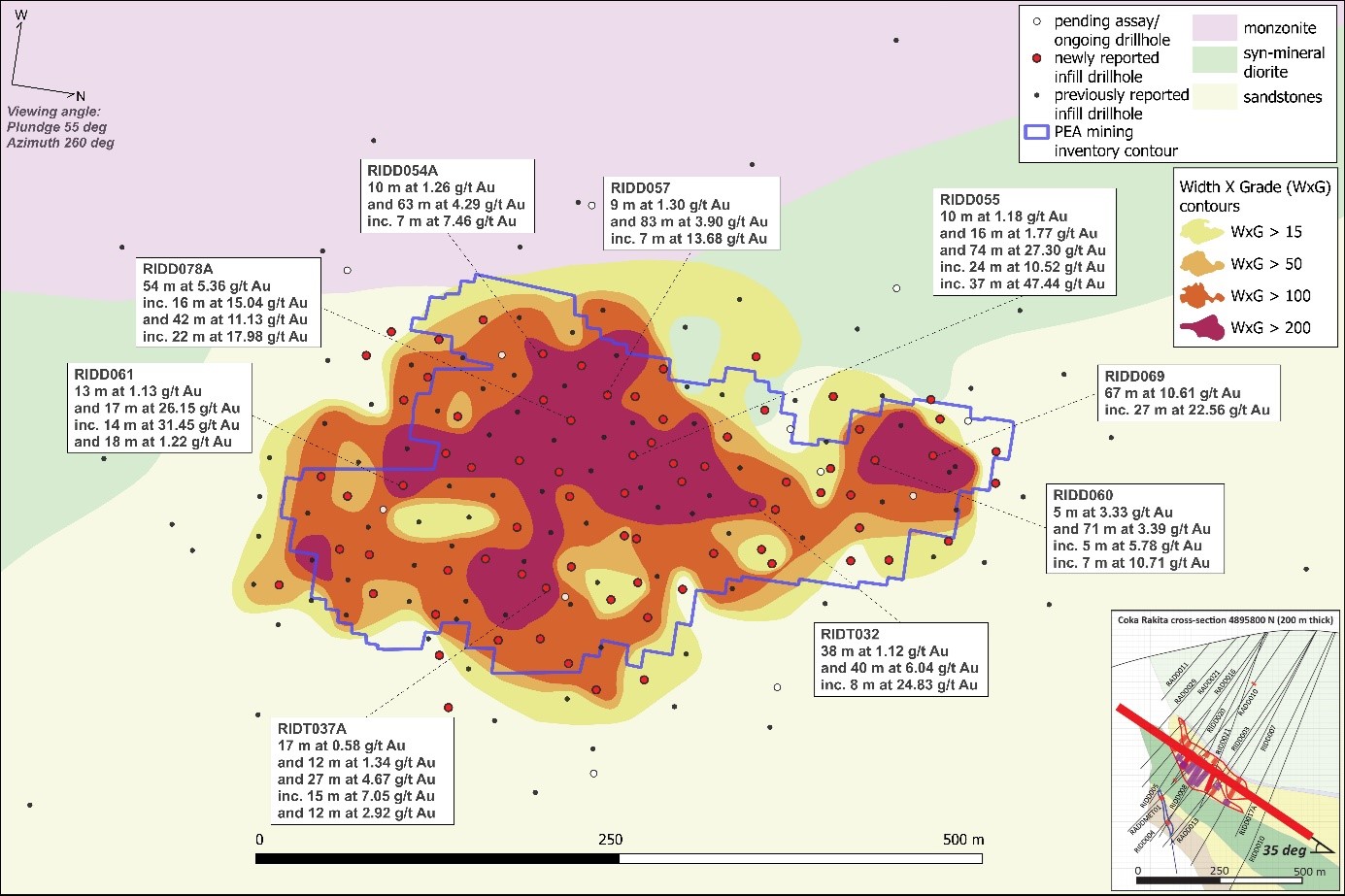

- Completion of the PFS infill drilling program: Results continue to confirm the continuity of a core zone of high-grade mineralization with the Mineral Resource outline (see Figure 1 ). Highlights include:

- RIDD055 – 74 metres at 27.3 g/t Au, from 426 metres downhole,

including 37 metres at 47.44 g/t Au and 0.11% Cu from 460 metres downhole. - RIDD057 – 83 metres at 3.90 g/t Au and 0.24% Cu from 385 metres.

- RIDD060 – 71 metres at 3.39 g/t Au from 414 metres,

including 7 metres at 10.71 g/t Au from 473 metres downhole. - RIDD069 – 67 metres at 10.61 g/t Au and 0.23% Cu, from 387 metres.

- RIDD078A – 42 metres at 11.13 g/t Au and 0.18 % Cu from 263 metres.

- RIDD055 – 74 metres at 27.3 g/t Au, from 426 metres downhole,

Visit https://vrify.com/decks/16804 to view an interactive 3D model highlighting these results.

“We continue to unlock Čoka Rakita’s potential to add production growth and strong margins to our portfolio, with first production targeted for 2028,” said David Rae, President and Chief Executive Officer.

“As we accelerate the project through our development pipeline, we are progressing the PFS, which remains on track for Q1 2025, and advancing permitting activities to support start-up of construction in 2026.

“We have the financial and technical resources to advance this high-quality growth project and continue our exploration programs to further define the significant potential of Čoka Rakita and the surrounding licences.”

Čoka Rakita Project Update

DPM continues to advance the Čoka Rakita project, with first production of concentrate targeted for 2028. The PFS is advancing well and remains on track for completion in the first quarter of 2025.

With the completion of the PFS infill drilling program, discussed below, the Company is now updating the Mineral Resource Estimate (“MRE”). All planned trade-off studies have been completed, allowing DPM to advance the flowsheet and site layout for the PFS engineering and permitting process. In addition, the geotechnical and hydrogeological drilling program, which will support the PFS design and cost estimates, is nearing completion. Metallurgical testwork results continue to support the assumption of approximately 90% gold recovery by gravity concentration and conventional flotation outlined in the preliminary economic assessment issued in May 2024. 1

In parallel, permitting activities have continued to advance. Baseline monitoring studies for the environmental impact assessment are expected to be submitted in the first quarter of 2026. Permitting preparation activities are underway, with a detailed timeline focused on supporting commencement of construction in mid-2026. The Company has had a local presence in Serbia since 2004 and has developed strong relationships in the region and will continue its proactive engagement with all stakeholders as the project advances.

Čoka Rakita benefits from good infrastructure, including nearby existing roads and power lines. The project is a strong fit with the Company’s underground mining and processing expertise and is in close regional proximity to DPM’s existing operations in Bulgaria, with opportunities to leverage existing technical, administration and permitting functions as well as transfer of knowledge and skills.

Infill Drilling Program Results

The PFS infill drilling program at Čoka Rakita focused on upgrading of the MRE to an Indicated Mineral Resource category, with an additional 30,900 metres of drilling and new results from 68 drill holes completed since the Company’s previous update in February 2024.

With the PFS infill drilling now complete, drill hole spacing is approximately 30 metres by 30 metres over the deposit footprint, with some areas locally reaching a tighter grid, nearing 20 metres by 20 metres within the high-grade core of the deposit.

Results from the infill drilling program returned numerous wide and high-grade gold intercepts that confirm the continuity of a core zone of high-grade gold mineralization within the Mineral Resource outline (see Figure 1 ). This is particularly evident in holes RIDD054A, RIDD055, RIDD057 and RIDD078, which returned intervals within the higher-grade core zone that correlate well with neighbouring drill holes.

1 Refer to the news release dated May 1, 2024, and the Čoka Rakita Technical Report “Preliminary Economic Assessment – Čoka Rakita Project, Eastern Serbia,” dated June 11, 2024, both available at www.dundeeprecious.com .

An updated MRE for Čoka Rakita, which is currently underway, will build on the maiden MRE, announced in December 2023, 2 incorporating a more detailed understanding of the geologic controls and deposit architecture. Interpretations of the mineralization include improved modelling approaches of late-stage intrusive sills, as well as a more constrained domaining strategy. Initial testing of MRE parameters indicates that more selective estimation approaches are appropriate, relative to the previous estimate, given the geostatistical and geometallurgical characteristics observed.

For the full results of the 68 new infill drill holes, refer to Table 1 of this news release. The table includes new screen fire assay results from drill holes RIDD049, RIDD049A, RIDD050, RIDD050A, RIDD052, RIDD052A, RIDT030A, RIDT030B and RIDT036A, which were previously reported in February 2024 using 50g fire assay results. 3

Additional near-resource extension and definition drilling is ongoing and is focused on locally ascertaining the orientation of structurally controlled mineralization on the eastern flank of the deposit, as well as testing potential extensions of sandstone hosted mineralization that may persist towards the northwest and southwest. Technical drilling programs continue to evaluate local variability of geotechnical and hydrogeological conditions for improved understanding.

2 Refer to the news release dated December 11, 2023, and the Čoka Rakita Technical Report dated June 11, 2024, both available at www.dundeeprecious.com .

3 For more information regarding DPM’s previously reported infill drilling results at Čoka Rakita, refer to the Company’s news release dated February 26, 2024, available on our website at www.dundeeprecious.com .

Figure 1. Tilted slice along high-grade skarn mineralization highlighting new intercepts from the infill drilling program at Čoka Rakita.

Table 1: New drill intercepts from the Čoka Rakita infill drilling.

| HOLEID | EAST | NORTH | RL | AZ | DIP | FROM | TO | LENGTH | AuEq | Au | Cu |

| (m) | (m) | (m) | (g/t) | (g/t) | (%) | ||||||

| RIDD049 | 573255 | 4895878 | 927 | 267 | -61 | 609 | 619 | 10 | 1.86 | 1.86 | - |

| and | 625 | 651 | 26 | 6.00 | 6.00 | - | |||||

| including | 633 | 648 | 15 | 9.64 | 9.64 | - | |||||

| RIDD049A | 573048 | 4895878 | 562 | 273 | -63 | 195 | 245 | 50 | 1.98 | 1.98 | - |

| RIDD050 | 573042 | 4895848 | 919 | 260 | -64 | 129 | 137 | 8 | 1.45 | 1.45 | - |

| and | 423 | 428 | 5 | 3.62 | 3.62 | - | |||||

| and | 470 | 502 | 32 | 12.66 | 12.66 | - | |||||

| RIDD050A | 572933 | 4895829 | 693 | 258 | -64 | 192 | 204 | 12 | 7.84 | 7.84 | - |

| including | 194 | 204 | 10 | 8.99 | 8.99 | - | |||||

| and | 218 | 264 | 46 | 8.50 | 8.50 | - | |||||

| including | 226 | 245 | 19 | 14.90 | 14.90 | - | |||||

| including | 249 | 259 | 10 | 7.32 | 7.32 | - | |||||

| RIDD051 | 573095 | 4895789 | 931 | 265 | -73 | 140 | 148 | 8 | 3.21 | 3.21 | - |

| and | 156 | 161 | 5 | 2.05 | 2.05 | - | |||||

| and | 509 | 549 | 40 | 5.56 | 5.56 | - | |||||

| including | 521 | 537 | 16 | 11.81 | 11.81 | - | |||||

| RIDD051A | 573003 | 4895782 | 643 | 266 | -71 | 182 | 199 | 17 | 2.54 | 2.54 | - |

| and | 210 | 238 | 28 | 3.19 | 3.19 | - | |||||

| including | 225 | 233 | 8 | 9.00 | 9.00 | - | |||||

| RIDD052 | 572997 | 4895940 | 915 | 271 | -67 | 380 | 387 | 7 | 1.13 | 0.99 | 0.10 |

| and | 411 | 496 | 85 | 9.81 | 9.65 | 0.13 | |||||

| including | 474 | 490 | 16 | 39.58 | 39.36 | 0.16 | |||||

| RIDD052A | 572885 | 4895946 | 649 | 271 | -69 | 94 | 100 | 6 | 2.20 | 1.71 | 0.36 |

| and | 123 | 203 | 80 | 53.38 | 53.18 | 0.15 | |||||

| including | 133 | 144 | 11 | 8.19 | 7.91 | 0.21 | |||||

| including | 163 | 180 | 17 | 234.78 | 234.58 | 0.15 | |||||

| RIDD053 | 573040 | 4895848 | 919 | 270 | -66 | 438 | 447 | 9 | 0.90 | 0.90 | - |

| and | 481 | 520 | 39 | 3.30 | 3.30 | - | |||||

| including | 507 | 513 | 6 | 11.10 | 11.10 | - | |||||

| RIDD053A** | 572922 | 4895846 | 646 | 274 | -67 | 129 | 160 | 31 | 3.69 | ||

| and | 161 | 180 | 19 | 2.93 | |||||||

| and | 185 | 196 | 11 | 1.63 | |||||||

| and | 198 | 213 | 15 | 10.39 | |||||||

| RIDD054 | 572954 | 4895843 | 901 | 266 | -66 | 342 | 442 | 100 | 3.32 | 2.96 | 0.27 |

| including | 403 | 411 | 8 | 7.44 | 7.21 | 0.17 | |||||

| RIDD054A | 572840 | 4895838 | 652 | 271 | -65 | 74 | 84 | 10 | 1.47 | 1.26 | 0.15 |

| and | 91 | 154 | 63 | 4.55 | 4.29 | 0.19 | |||||

| including | 98 | 105 | 7 | 7.46 | 7.46 | - | |||||

| RIDD055 | 572999 | 4895938 | 915 | 257 | -65 | 357 | 367 | 10 | 1.18 | 1.18 | - |

| and | 401 | 417 | 16 | 1.77 | 1.77 | - | |||||

| and | 426 | 500 | 74 | 27.30 | 27.30 | - | |||||

| including | 427 | 451 | 24 | 10.52 | 10.52 | - | |||||

| including | 460 | 497 | 37 | 47.59 | 47.44 | 0.11 | |||||

| RIDD055A | 572888 | 4895914 | 657 | 259 | -68 | 128 | 206 | 78 | 9.38 | 9.19 | 0.13 |

| including | 149 | 182 | 33 | 15.54 | 15.40 | 0.11 | |||||

| including | 187 | 194 | 7 | 7.49 | 7.09 | 0.30 | |||||

| RIDD056 | 573195 | 4895772 | 940 | 282 | -65 | 530 | 567 | 37 | 3.23 | 3.23 | - |

| including | 548 | 553 | 5 | 6.03 | 6.03 | - | |||||

| and | 605 | 638 | 33 | 2.00 | 2.00 | - | |||||

| RIDD056A** | 573077 | 4895801 | 691 | 283 | -61 | 299 | 322 | 23 | 1.26 | ||

| and | 340 | 364 | 24 | 3.24 | |||||||

| including | 346 | 354 | 8 | 6.16 | |||||||

| RIDD057 | 573001 | 4895938 | 915 | 255 | -62 | 369 | 378 | 9 | 1.30 | 1.30 | - |

| and | 385 | 468 | 83 | 4.22 | 3.90 | 0.24 | |||||

| including | 460 | 467 | 7 | 14.12 | 13.68 | 0.32 | |||||

| RIDD057A** | 572882 | 4895909 | 670 | 256 | -64 | 103 | 109 | 6 | 3.54 | 3.04 | 0.37 |

| and | 120 | 135 | 15 | 1.04 | |||||||

| and | 154 | 173 | 19 | 3.5 | |||||||

| and | 187 | 196 | 9 | 7.28 | |||||||

| RIDD058 | 573221 | 4895694 | 938 | 278 | -61 | 556 | 601 | 45 | 1.89 | 1.89 | - |

| RIDD059 | 573086 | 4895929 | 920 | 260 | -63 | 217 | 224 | 7 | 3.82 | 3.82 | - |

| and | 446 | 451 | 5 | 1.25 | 0.91 | 0.25 | |||||

| and | 479 | 536 | 57 | 7.01 | 7.01 | 0.03 | |||||

| including | 501 | 516 | 15 | 9.68 | 9.68 | - | |||||

| including | 520 | 531 | 11 | 14.38 | 14.38 | - | |||||

| RIDD060** | 572904 | 4896042 | 912 | 277 | -75 | 401 | 406 | 5 | 3.33 | ||

| and | 414 | 485 | 71 | 3.39 | |||||||

| including | 449 | 454 | 5 | 5.78 | |||||||

| including | 473 | 480 | 7 | 10.71 | |||||||

| RIDD060A** | 572835 | 4896048 | 640 | 275 | -75 | 146 | 166 | 20 | 7.67 | ||

| including | 147 | 156 | 9 | 15.31 | |||||||

| RIDD061 | 573094 | 4895788 | 931 | 263 | -63 | 474 | 487 | 13 | 1.13 | 1.13 | - |

| and | 499 | 516 | 17 | 26.15 | 26.15 | - | |||||

| including | 501 | 515 | 14 | 31.45 | 31.45 | - | |||||

| and | 531 | 549 | 18 | 1.63 | 1.22 | 0.30 | |||||

| RIDD061A** | 572966 | 4895770 | 680 | 262 | -62 | 206 | 249 | 43 | 10.79 | ||

| including | 221 | 230 | 9 | 32.93 | |||||||

| RIDD062 | 572853 | 4896121 | 900 | 252 | -78 | 387 | 406 | 19 | 1.08 | 0.81 | 0.2 |

| RIDD062A | 572792 | 4896099 | 609 | 250 | -78 | no significant intervals | |||||

| RIDD063 | 573087 | 4895929 | 920 | 258 | -71 | 430 | 443 | 13 | 0.98 | 0.98 | - |

| and | 500 | 525 | 25 | 0.96 | 0.96 | - | |||||

| RIDD063A** | 572987 | 4895910 | 633 | 266 | -70 | 135 | 165 | 30 | 2.47 | ||

| including | 150 | 155 | 5 | 6.33 | |||||||

| and | 199 | 225 | 26 | 2.61 | |||||||

| including | 199 | 204 | 5 | 8.80 | |||||||

| RIDD064** | 573050 | 4896005 | 910 | 245 | -71 | 545 | 552 | 7 | 1.17 | ||

| RIDD065** | 572904 | 4896042 | 912 | 258 | -79 | 435 | 445 | 10 | 1.11 | ||

| and | 461 | 466 | 5 | 2.03 | |||||||

| RIDD066** | 573022 | 4895686 | 928 | 283 | -58 | 155 | 163 | 8 | 5.76 | 5.76 | - |

| and | 452 | 457 | 5 | 1.24 | |||||||

| RIDD066A | 572877 | 4895717 | 688 | 281 | -58 | no significant intervals | |||||

| RIDD067 | 572971 | 4896085 | 903 | 285 | -71 | 477 | 507 | 30 | 0.96 | 0.96 | - |

| RIDD068* | 573144 | 4895675 | 943 | 278 | -66 | 548 | 587 | 39 | 2.64 | 2.64 | - |

| RIDD068A | 572995 | 4895699 | 613 | 287 | -64 | aborted for technical reasons | |||||

| RIDD068B** | 573004 | 4895696 | 633 | 285 | -64 | 207 | 230 | 23 | 5.12 | ||

| including | 208 | 224 | 16 | 6.88 | |||||||

| RIDD069 | 572851 | 4896120 | 900 | 243 | -82 | 387 | 454 | 67 | 10.92 | 10.61 | 0.23 |

| including | 419 | 446 | 27 | 23.05 | 22.56 | 0.36 | |||||

| RIDD070 | 573048 | 4896006 | 910 | 271 | -69 | aborted for technical reasons | |||||

| RIDD071* | 573092 | 4895927 | 920 | 260 | -67 | 478 | 498 | 20 | 1.19 | 1.19 | - |

| and | 516 | 528 | 12 | 2.04 | 2.04 | - | |||||

| RIDD072* | 573093 | 4895789 | 931 | 245 | -65 | 508 | 521 | 13 | 3.89 | 3.89 | |

| RIDD073 | 572855 | 4896122 | 900 | 291 | -83 | no significant intervals | |||||

| RIDD073A | 572824 | 4896135 | 629 | 300 | -83 | no significant intervals | |||||

| RIDD073B | 572808 | 4896145 | 479 | 302 | -83 | aborted for technical reasons | |||||

| RIDD074* | 572903 | 4896043 | 912 | 260 | -78 | 396 | 404 | 8 | 1.53 | 1.23 | 0.22 |

| and | 421 | 428 | 7 | 1.37 | 1.11 | 0.19 | |||||

| and | 439 | 454 | 15 | 1.08 | 0.77 | 0.23 | |||||

| RIDD075* | 572968 | 4896089 | 903 | 265 | -77 | 479 | 484 | 5 | 1.90 | 1.73 | 0.12 |

| RIDD075A* | 572910 | 4896092 | 659 | 265 | -78 | 183 | 190 | 7 | 1.00 | 0.66 | 0.25 |

| and | 234 | 247 | 13 | 2.30 | 2.16 | 0.10 | |||||

| RIDD076* | 572998 | 4895939 | 915 | 261 | -60 | 382 | 400 | 18 | 1.13 | 0.62 | 0.38 |

| and | 425 | 438 | 13 | 10.89 | 10.35 | 0.40 | |||||

| RIDD077 | 573198 | 4895770 | 940 | 272 | -66 | 529 | 542 | 13 | 2.80 | 2.80 | - |

| and | 575 | 617 | 42 | 2.41 | 2.41 | - | |||||

| including | 590 | 598 | 8 | 6.66 | 6.66 | - | |||||

| RIDD077A** | 573066 | 4895777 | 647 | 272 | -64 | 242 | 258 | 16 | 3.88 | ||

| RIDD078* | 573045 | 4895853 | 919 | 270 | -61 | 400 | 415 | 15 | 2.24 | 2.24 | - |

| and | 421 | 450 | 29 | 2.30 | 2.30 | - | |||||

| and | 458 | 501 | 43 | 11.05 | 10.85 | 0.15 | |||||

| including | 471 | 492 | 21 | 20.91 | 20.77 | 0.10 | |||||

| RIDD078A* | 572950 | 4895853 | 741 | 271 | -62 | 199 | 253 | 54 | 5.36 | 5.36 | - |

| including | 231 | 247 | 16 | 15.04 | 15.04 | - | |||||

| and | 263 | 305 | 42 | 11.37 | 11.13 | 0.18 | |||||

| including | 276 | 298 | 22 | 18.25 | 17.98 | 0.20 | |||||

| RIDD079* | 573023 | 4895685 | 928 | 277 | -62 | 166 | 178 | 12 | 4.93 | 4.93 | - |

| including | 169 | 174 | 5 | 8.46 | 8.46 | - | |||||

| RIDD080* | 572903 | 4896043 | 912 | 261 | -73 | 393 | 406 | 13 | 2.76 | 2.43 | 0.25 |

| RIDD081 | 572915 | 4895986 | 911 | 266 | -72 | no significant intervals | |||||

| RIDD082* | 573000 | 4895943 | 915 | 277 | -66 | 320 | 328 | 8 | 1.21 | 1.21 | - |

| and | 425 | 464 | 39 | 1.87 | 1.72 | 0.11 | |||||

| RIDD083* | 573096 | 4895787 | 931 | 267 | -58 | 513 | 528 | 15 | 4.19 | 3.99 | 0.15 |

| RIDD084 | 572967 | 4896088 | 903 | 274 | -70 | aborted for technical reasons | |||||

| RIDD085** | 572954 | 4895850 | 901 | 248 | -63 | 366 | 398 | 32 | 2.14 | ||

| RIDD086 | 572913 | 4895985 | 910 | 276 | -76 | no significant intervals | |||||

| RIDD087** | 573024 | 4895687 | 928 | 282 | -67 | 440 | 447 | 7 | 1.20 | ||

| and | 466 | 471 | 5 | 1.39 | |||||||

| and | 487 | 494 | 7 | 13.63 | |||||||

| including | 488 | 494 | 6 | 15.57 | |||||||

| RIDD088** | 573000 | 4895942 | 915 | 262 | -65 | 420 | 453 | 33 | 5.06 | ||

| including | 426 | 434 | 8 | 11.39 | |||||||

| RIDD089** | 573090 | 4895926 | 920 | 270 | -59 | 428 | 450 | 22 | 8.85 | ||

| RIDD090 | 572996 | 4895775 | 913 | 274 | -63 | completed / awaiting results | |||||

| RIDD091 | 573048 | 4896010 | 910 | 290 | -62 | completed / awaiting results | |||||

| RIDD092 | 572591 | 4896071 | 846 | 105 | -54 | in progress | |||||

| RIDD093 | 572715 | 4895835 | 838 | 119 | -61 | in progress | |||||

| RIDT030A | 572894 | 4896040 | 647 | 293 | -70 | 162 | 215 | 53 | 2.65 | 2.32 | 0.25 |

| including | 202 | 208 | 6 | 8.46 | 8.22 | 0.18 | |||||

| RIDT030B | 572884 | 4896044 | 619 | 291 | -69 | 106 | 116 | 10 | 1.33 | 0.75 | 0.43 |

| and | 125 | 137 | 12 | 1.13 | 0.80 | 0.24 | |||||

| and | 147 | 168 | 21 | 1.16 | 0.89 | 0.20 | |||||

| RIDT032 | 572991 | 4896003 | 916 | 266 | -68 | 406 | 444 | 38 | 1.46 | 1.12 | 0.26 |

| and | 460 | 500 | 40 | 6.04 | 6.04 | - | |||||

| including | 470 | 478 | 8 | 25.01 | 24.83 | 0.14 | |||||

| RIDT032A | 572884 | 4895996 | 639 | 267 | -73 | 150 | 161 | 11 | 1.20 | 0.90 | 0.22 |

| and | 169 | 193 | 24 | 3.55 | 3.32 | 0.17 | |||||

| and | 206 | 212 | 6 | 1.03 | 1.03 | - | |||||

| RIDT033** | 572992 | 4896001 | 917 | 265 | -76 | 380 | 391 | 11 | 1.75 | ||

| RIDT033A | 572915 | 4895992 | 621 | 266 | -76 | 170 | 180 | 10 | 2.69 | 2.69 | - |

| RIDT036A | 572963 | 4895878 | 610 | 253 | -66 | 156 | 196 | 40 | 2.36 | 2.22 | 0.10 |

| RIDT037 | 573086 | 4895926 | 920 | 250 | -70 | 455 | 471 | 16 | 2.54 | 2.54 | - |

| and | 492 | 534 | 42 | 6.89 | 6.89 | - | |||||

| including | 501 | 519 | 18 | 5.62 | 5.62 | - | |||||

| and | 540 | 553 | 13 | 1.17 | 1.17 | - | |||||

| RIDT037A | 572987 | 4895883 | 643 | 245 | -69 | 134 | 151 | 17 | 1.41 | 0.58 | 0.62 |

| and | 176 | 188 | 12 | 1.34 | 1.34 | - | |||||

| and | 195 | 222 | 27 | 4.67 | 4.67 | - | |||||

| including | 201 | 216 | 15 | 7.05 | 7.05 | - | |||||

| and | 233 | 245 | 12 | 3.06 | 2.92 | 0.10 | |||||

| RIDT038 | 573085 | 4895929 | 920 | 262 | -69 | 466 | 471 | 5 | 1.14 | 1.14 | - |

| and | 479 | 484 | 5 | 1.38 | 1.38 | - | |||||

| and | 507 | 526 | 19 | 5.11 | 4.95 | 0.12 | |||||

| RIDT038A | 572976 | 4895914 | 632 | 263 | -70 | 196 | 210 | 14 | 1.26 | 0.99 | 0.19 |

| RIDT041* | 573250 | 4895885 | 927 | 275 | -61 | 620 | 636 | 16 | 2.46 | 2.46 | - |

| including | 629 | 634 | 5 | 5.29 | 5.29 | - | |||||

| RIDT043A | 573150 | 4895774 | 833 | 280 | -64 | no significant intervals | |||||

| RADDHG002* | 573144 | 4895669 | 943 | 268 | -69 | 560 | 593 | 33 | 2.95 | 2.95 | - |

| RADDHG003* | 573024 | 4895687 | 928 | 267 | -73 | 481 | 501 | 20 | 6.78 | 6.78 | - |

| including | 487 | 493 | 6 | 18.52 | 18.52 | - | |||||

| RADDHG004** | 573043 | 4895851 | 919 | 260 | -71 | 471 | 495 | 24 | 3.49 | ||

| and | 502 | 507 | 5 | 4.2 | |||||||

| RADDHG005 | 572810 | 4895874 | 869 | 85.8 | -64 | completed / awaiting results | |||||

| RADDHG006 | 572739 | 4895865 | 850 | 233 | -80 | completed / awaiting results | |||||

| RADDHG007 | 572995 | 4896004 | 917 | 355 | -67 | completed / awaiting results | |||||

| RADDHG008 | 572992 | 4896006 | 917 | 275 | -85 | in progress | |||||

| RADDGTH001 | 572707 | 4895652 | 826 | 65.7 | -75 | completed / awaiting results | |||||

| RADDGTH002 | 572694 | 4896102 | 873 | 161 | -80 | completed / awaiting results | |||||

| RADDGTH003* | 572914 | 4895986 | 910 | 227 | -84 | 363 | 380 | 17 | 3.44 | 3.2 | 0.18 |

| including | 365 | 370 | 5 | 7.67 | 7.24 | 0.32 | |||||

| and | 400 | 406 | 6 | 1.6 | 1.29 | 0.23 | |||||

| and | 434 | 448 | 14 | 1.12 | 1.01 | - | |||||

| and | 450 | 464 | 14 | 1.71 | 1.61 | - | |||||

| RADDGTH004* | 572801 | 4895680 | 857 | 11.8 | -77 | 23 | 29 | 6 | 1.59 | 1.25 | 0.25 |

| and | 367 | 377 | 10 | 6.84 | 6.84 | - | |||||

| including | 372 | 377 | 5 | 11.09 | 11.09 | - | |||||

| and | 378 | 396 | 18 | 4.46 | 4.30 | 0.11 | |||||

| including | 378 | 384 | 6 | 11.49 | 11.21 | 0.21 | |||||

| RADDGTH005** | 572771 | 4896030 | 887 | 185 | -80 | 155 | 163 | 8 | 1.05 | ||

| and | 309 | 321 | 12 | 1.25 | 0.81 | 0.33 | |||||

| RADDGTH006 | 572903 | 4896043 | 912 | 302 | -70 | completed / awaiting results | |||||

| RADDGTH007 | 572813 | 4895875 | 869 | 100 | -74 | in progress | |||||

| 1) | Coordinates are in UTM Zone 34 North WGS84 datum. |

| 2) | Intervals are reported at a cut-off grade of 1 g/t AuEq using 5 metres minimum length and 5 metres maximum internal dilution. Higher grade sub-intervals denoted with ‘Including’ are reported at a cut-off grade of 5 g/t AuEq using 5 metres minimum length and 3 metres maximum internal dilution. |

| 3) | The AuEq calculation is based on the following formula: Au g/t + 1.35 x Cu %, based on a gold price of $1,400/oz. and a copper price of $2.75/lb.; and assumes metallurgical recoveries of 90% for gold and 90% for copper within the equivalency calculation. These assumptions are based on PEA level metallurgical testwork results. Copper below 0.1% has not been reported and is not included in the equivalency calculation. |

| 4) | No upper cuts have been applied. |

| 5) | Based on the current understanding of the geometry of the mineralized body, true widths are considered to be 90% or more of the reported downhole interval. |

| 6) | “DT” within the hole naming nomenclature (e.g. RIDT005) indicates that the hole is a diamond tail of a reverse circulation pre-collar drillhole. |

| 7) | Daughter holes identified with “A” (e.g. RIDT030A) are navigational holes with collar coordinates and depth indicating the exit point from the parent hole. |

| 8) | “HG” within the hole naming nomenclature (e.g. RADDHG001) indicates that the hole is a hydrogeological monitoring hole. |

| 9) | “GTH” within the hole naming nomenclature (e.g. RADDGTH001) indicates that the hole is drilled for geotechnical purposes. |

| 10) | Holes marked with (*) have been assayed using a 50 g Fire Assay method, Screen Fire Assays (SFA) results pending. |

| 11) | Holes marked with (* *) have been reported only based on Au assays as Cu assays are pending. |

Sampling, Analysis and QAQC of Exploration Drill Core Samples

Given the presence of coarse gold at Čoka Rakita, a rigorous sampling and QAQC procedure has been selected which includes the use of laboratory screen metallic assaying.

Most exploration diamond drill holes are collared with PQ size, continued with HQ, and are sometimes finished with NQ. Triple tube core barrels and short runs are used whenever possible to improve recovery. All drill core is cut lengthwise into two halves using a diamond saw: one half is sampled for assaying and the other half is retained in core trays. The common length for sample intervals within mineralized zones is one metre. Weights of drill core samples range from three to eight kilograms (“kg”), depending on the size of core, rock type, and recovery. A numbered tag is placed into each sample bag, and the samples are grouped into batches for laboratory submission.

Drill core samples are shipped to the Company’s own exploration laboratory in Bor, Serbia, which is independently managed by SGS. SGS methods and procedures are accredited at SGS hub labs and independent internal lab QAQC check samples are sent to an SGS accredited laboratory. The Bor lab also participate in SGS monthly round robins, and other international round robins. Quality control samples, comprising certified reference materials, blanks, and field duplicates, are inserted into each batch of samples and locations for crushed duplicates and pulp replicates are specified. All drill core and quality control samples are tabulated on sample submission forms that specify sample preparation procedures and codes for analytical methods. For internal quality control, the laboratory includes its own quality control samples comprising certified reference materials, blanks and pulp duplicates. All QAQC monitoring data are reviewed, verified and signed off by an independent QAQC geologist. Chain of custody records are maintained from sample shipments to the laboratory until analyses are completed and remaining sample materials are returned to the Company. The chain of custody is transferred from the Company to SGS at the laboratory door.

At the SGS Bor laboratory, the submitted drill core samples are dried at 105°C for a minimum of 12 hours, and then jaw crushed to approximately 80% passing four millimetres. Sample preparation duplicates are created by riffle splitting crushed samples on a 1-in-20 basis. Larger samples are riffle split prior to pulverizing, whereas smaller samples are pulverized entirely. Pulverization specifications are 90% passing 75 microns. Gold analyses are done using a conventional 50-gram fire assay and AAS finish. Multi-element analyses for 49 elements, including Ag, Cu, Mo, As, Bi, Pb, Sb, and Zn, are done using a four-acid digestion and an ICP-MS finish at SGS Bor and SGS Ankara laboratories. Samples returning over 10 ppm for Ag and 1% for Cu, Pb or Zn are re-analyzed with AAS finish. Sulphur is analyzed using an Eltra Analyzer equipped with an induction furnace.

All fire assays performed at SGS Bor with results exceeding 1 g/t gold grade from the Čoka Rakita deposit are re-assayed by means of a specifically designed gold screen fire assay program at the ALS Global laboratory located in Romania. For re-analyses, 1 kg of 2 mm sized coarse reject material is split, pulverized and screened at 106 microns to separate the sample into a coarse fraction (>106 µm) and a fine fraction (<106 µm). After screening, two 50-gram aliquots of the fine fraction are analyzed using the traditional fire assay method and AAS finish. The entire coarse fraction is assayed to determine the contribution of the coarse gold using fire assay and gravimetric finish. A “total” gold calculation for the 1kg sample is based on the weighted average of the coarse and fine fractions.

Technical Information

Ross Overall, Corporate Director Technical Services of the Company, who is a Qualified Person as defined under NI 43-101, and Paul Ivascanu, General Manager, Exploration of the Company, have reviewed, and approved the scientific and technical content of this news release. Mr. Overall has verified the accuracy of the information presented in this disclosure.

About Dundee Precious Metals

Dundee Precious Metals Inc. is a Canadian-based international gold mining company with operations and projects located in Bulgaria, Serbia and Ecuador. The Company’s purpose is to unlock resources and generate value to thrive and grow together. This overall purpose is supported by a foundation of core values, which guides how the Company conducts its business and informs a set of complementary strategic pillars and objectives related to ESG, innovation, optimizing our existing portfolio, and growth. The Company’s resources are allocated in-line with its strategy to ensure that DPM delivers value for all of its stakeholders. DPM’s shares are traded on the Toronto Stock Exchange (symbol: DPM).

For further information please contact:

| David Rae President and Chief Executive Officer Tel: (416) 365-5191 moc.suoicerpeednud@ofni.rotsevni |

Jennifer Cameron Director, Investor Relations Tel: (416) 219-6177 moc.suoicerpeednud@noremacj |

Cautionary Note Regarding Forward Looking Statements

This news release contains “forward looking statements” or “forward looking information” (collectively, “Forward Looking Statements”) that involve a number of risks and uncertainties. Forward Looking Statements are statements that are not historical facts and are generally, but not always, identified by the use of forward looking terminology such as “plans”, “expects”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “outlook”, “intends”, “anticipates”, “believes”, or variations of such words and phrases or that state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved, or the negative of any of these terms or similar expressions. The Forward Looking Statements in this news release relate to, among other things: future exploration potential at Čoka Rakita; additional potential of sandstone hosted mineralization; timing for the submission of the environmental impact assessment, the completion of the preliminary feasibility study, commencement of construction and production of first concentrate for Čoka Rakita; the geology and metallurgy at Čoka Rakita; Čoka Rakita’s potential for high margin production; the price of commodities; metallurgical recoveries; the future estimation of Mineral Resources and the realization of such mineral estimates; and success of exploration activities. Forward Looking Statements are based on certain key assumptions and the opinions and estimates of management and the Qualified Persons, as of the date such statements are made, and they involve known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements of the Company to be materially different from any other future results, performance or achievements expressed or implied by the Forward Looking Statements. In addition to factors already discussed in this news release, such factors include, among others, fluctuations in foreign exchange rates; risks arising from the current inflationary environment and the impact on operating costs and other financial metrics, including risks of recession; continuation or escalation of the conflict in Ukraine or elsewhere in the world; risks relating to the Company’s business generally and the impact of global pandemics, including COVID-19, resulting in changes to the Company’s supply chain, product shortages, delivery and shipping issues; possible variations in ore grade and recovery rates; inherent uncertainties in respect of conclusions of economic evaluations, economic studies and mine plans; changes in project parameters, including schedule and budget, as plans continue to be refined; uncertainties with respect to actual results of current exploration activities; uncertainties and risks inherent to developing and commissioning new mines into production, which may be subject to unforeseen delays and additional costs; uncertainties inherent with conducting business in foreign jurisdictions where corruption, civil unrest, political instability and uncertainties with the rule of law may impact the Company’s activities; limitations on insurance coverage; accidents, labour disputes and other risks of the mining industry; delays in obtaining governmental approvals or financing or in the completion of development or construction activities; opposition by social and non-governmental organizations to mining projects and smelting operations; unanticipated title disputes; claims or litigation; increased costs and physical risks, including extreme weather events and resource shortages, related to climate change; cyber-attacks and other cybersecurity risks; as well as those risk factors discussed or referred to in any other documents (including without limitation the Company’s most recent Annual Information Form) filed from time to time with the securities regulatory authorities in all provinces and territories of Canada and available on SEDAR+ at www.sedarplus.ca . The reader has been cautioned that the foregoing list is not exhaustive of all factors which may have been used. Although the Company has attempted to identify important factors that could cause actual actions, events or results to differ materially from those described in Forward Looking Statements, there may be other factors that cause actions, events or results not to be anticipated, estimated or intended. There can be no assurance that Forward Looking Statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. The Company’s Forward Looking Statements reflect current expectations regarding future events and speak only as of the date hereof. Unless required by securities laws, the Company undertakes no obligation to update Forward Looking Statements if circumstances or management’s estimates or opinions should change. Accordingly, readers are cautioned not to place undue reliance on Forward Looking Statements.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/bf112f38-9c9a-49be-bcb5-1eae9c969f48